Clear records

history record

Products

Contact

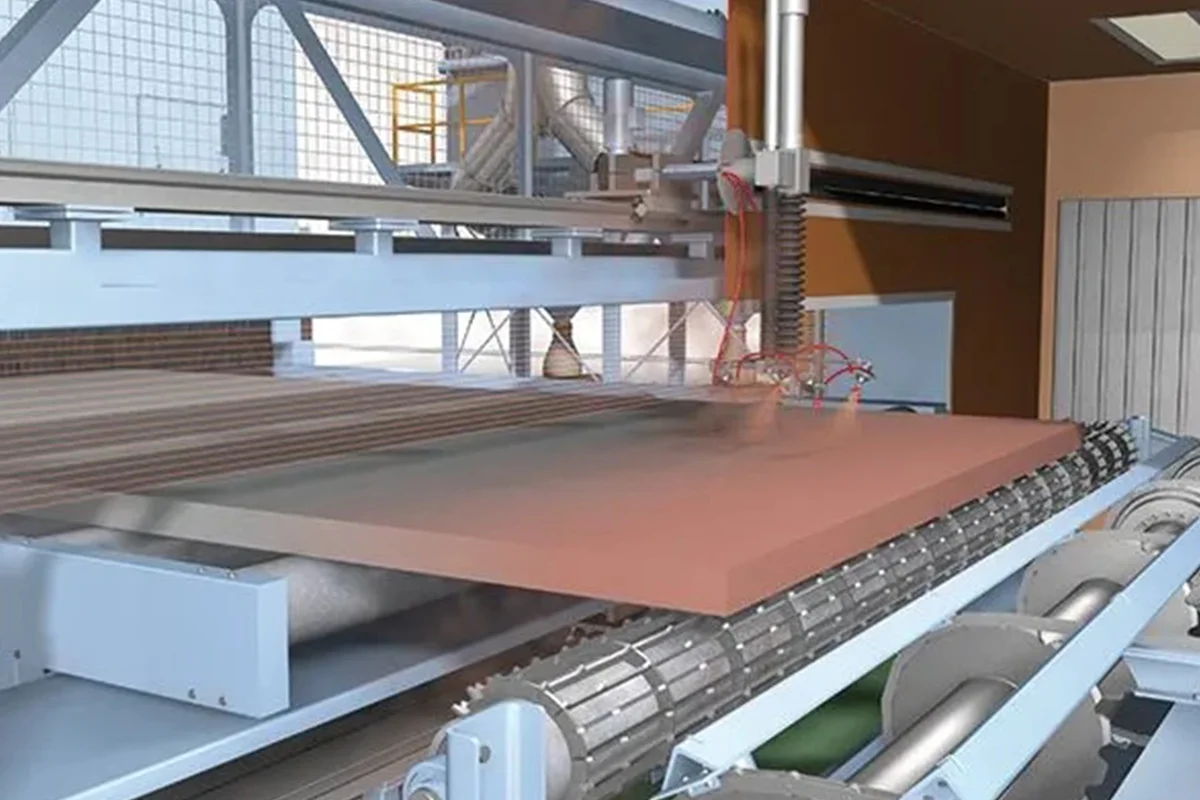

Sheet Metal Pre-Treatment Line

Sheet Metal Pre-Treatment Line

I. Introduction

With automation, high-efficiency cleaning, and precise coating technology, sheet metal pre-treatment lines are evolving toward intelligent, eco-friendly, and energy-efficient solutions to meet the growing market demands.

II. Application Areas

Automotive Manufacturing: Pre-treatment of vehicle body panels.

Home Appliance Manufacturing: Pre-treatment of refrigerator and washing machine casings.

Construction Industry: Pre-treatment of steel structures and curtain wall materials.

Shipbuilding: Pre-treatment of ship hull panels.

III. Technical Overview

1. Basic Principles

The sheet metal pre-treatment line is an automated production system designed for the surface treatment of metal sheets (such as steel and aluminum panels). The process enhances corrosion resistance, adhesion, and surface quality, preparing materials for subsequent processing (e.g., coating, welding).

2. Core Process Flow

Loading

Automatic or manual feeding of sheet metal into the production line.

Cleaning

Removal of surface contaminants such as oil, dust, and residues using alkaline or acidic cleaning agents.

Rinsing

Water rinsing to eliminate chemical residues from the cleaning process.

Surface Treatment

Phosphating, passivation, or oxidation to improve corrosion resistance and adhesion.

Drying

Hot air or infrared drying to ensure the sheet is completely dry before further processing.

Cooling

Natural or forced cooling to bring the sheet back to room temperature.

Unloading

Automatic or manual unloading of the processed sheet metal.

IV. Technical Advantages

1. High Automation

Reduces manual intervention, ensuring consistent quality and high productivity.

2. Efficient Cleaning

Advanced cleaning systems effectively remove oil, rust, and contaminants, ensuring optimal pre-treatment.

3. Precision Coating

Automated spraying systems ensure uniform application of pre-treatment agents, improving adhesion and corrosion resistance.

4. Energy-Saving & Eco-Friendly

Uses low-energy consumption equipment and environmentally friendly pre-treatment agents, reducing energy waste and emissions.

5. High Flexibility

Suitable for various sheet materials and sizes, meeting diverse production needs.

6. Quality Control

Real-time online monitoring ensures processing quality meets industry standards.

V. Development Trends

1. Intelligent Systems

IoT, big data, and AI-driven optimization for smart process management.

2. Eco-Friendly Innovations

Development of green pre-treatment agents and processes, reducing wastewater and VOC emissions.

3. Energy Efficiency

Adoption of more efficient equipment and processes to further reduce energy consumption.

4. Multi-Function Integration

Combining cleaning, coating, and drying into a single streamlined process to improve efficiency.

5. Adaptation to New Materials

Meeting the pre-treatment demands of new composite and high-strength materials.

6. Customization & Standardization

Tailored solutions for specific customer needs while promoting standardization for global market expansion.